High-frequency technology: The core code for heat sealing of leg airbags

Driven by both the upgrade of health consumption and innovation in smart hardware, the inflatable leg massager (leg compression sleeve) market has experienced explosive growth. These products utilize multi-chamber airbags with cyclic inflation/deflation to simulate manual massage techniques, effectively relieving leg fatigue and promoting blood circulation, making them a popular choice for home health care. However, the manufacturing process of their core component - the inflatable air bladder - directly determines product sealing, durability, and massage comfort.

.jpg)

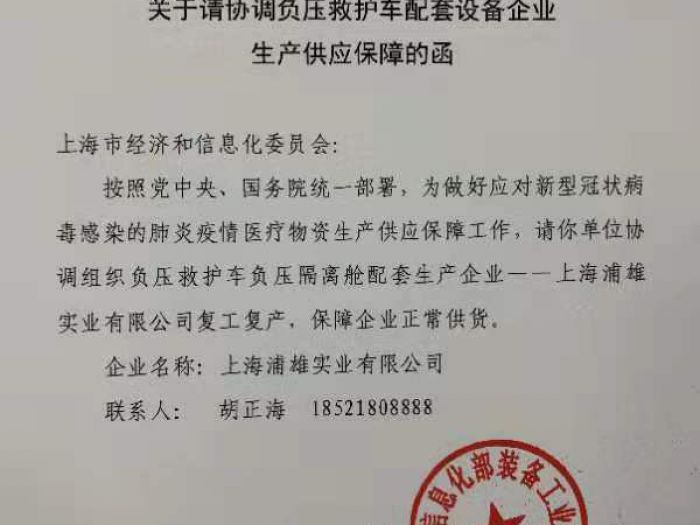

As an industry leader in high-frequency (HF) welding technology, Shanghai Puxiong Industrial Co., Ltd. has leveraged its decade-long technical expertise and multiple national invention patents to provide comprehensive solutions spanning from equipment R&D to process optimization for inflatable leg massager production.

HF Welding Technology: The Core Solution for Leg Air Bladder Fabrication Typically made of PVC or TPU materials known for flexibility, airtightness, and chemical resistance, leg massage air bladders face challenges like air leakage and cracking with traditional heat sealing or adhesive bonding. The HF welding technology addresses these by:

- Superior Sealing: 8mm+ weld width with ≥15N/15mm peel strength, exceeding industry standards for zero leakage under high pressure

- Material Versatility: Compatible with PVC, TPU, EVA, and blended materials (containing ≥10% PVC), adaptable to various hardness/elasticity requirements

- High Efficiency: 5-10 second cycle time per weld, achieving daily outputs of thousands via dual-station shuttle/turntable systems

Industry Applications: Full-scenario Coverage from Medical to Consumer Markets Puxiong's HF welding equipment serves multiple sectors:

- Medical-grade: ISO13485-certified sterile packaging systems produce hospital-grade compression therapy bladders enduring 100,000 inflation cycles

- Consumer Products: 0.3mm-thick e-commerce bestsellers withstand 0.08MPa pressure with return rates reduced from 8% to 1.5% using 15kW membrane HF machines

- Outdoor Gear: TPU-welded mountaineering leg protectors maintain elasticity at -30℃ for polar expeditions

This precise thermal fusion technology ensures reliable performance across temperature extremes while meeting strict medical compliance and mass production demands.