Face physical cooling TPU water bag mask how to produce

I. Design and Material Preparation

-

Demand Analysis

- Analyze market needs and user feedback to determine parameters such as size, shape, capacity, and fit of the water-bladder mask.

-

Structural Design

- Conceptualize and design the mask structure, including creating technical drawings and 3D models, ensuring a snug facial fit and effective physical cooling performance.

-

Material Selection

- Use high-quality TPU (Thermoplastic Polyurethane) as the primary material. TPU offers high elasticity, wear resistance, low-temperature resistance, and eco-friendliness, making it ideal for cold-therapy devices.

II. Mold Fabrication and Shaping

-

Mold Design

- Create molds based on design specifications. Precision and stability of molds are critical for product consistency and quality.

-

Mold Processing

- Use CNC machining to ensure smooth surfaces and accurate dimensions.

-

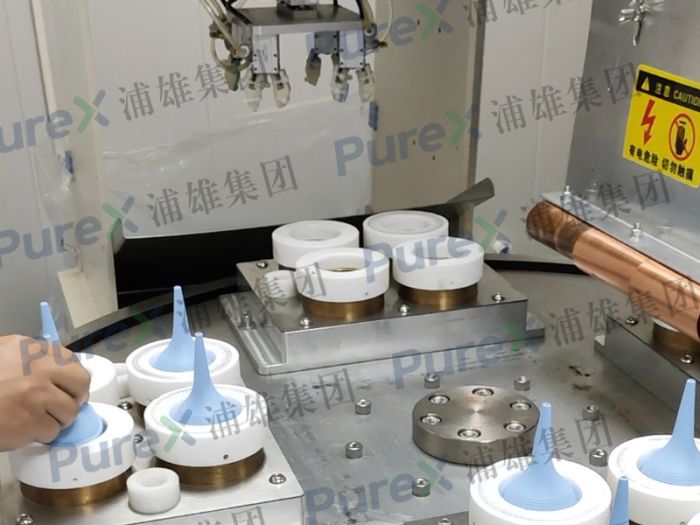

High-Frequency Heat Pressing

- Shape TPU sheets into the mask using high-frequency heat pressing. Temperature, pressure, and time are tightly controlled to ensure structural integrity and shape stability.

III. Water Circulation System Design

-

Pipeline Layout

- Design internal water channels to connect the mask with the cooling system.

-

Cooling Device

- Integrate a cooling unit to chill water to the desired temperature.

-

Circulation Pump

- Install a pump to drive water flow through the mask, ensuring continuous delivery of chilled water.

IV. Assembly and Testing

-

Assembly

- Assemble components (mask, water channels, cooling device, and pump) to ensure leak-proof connections.

-

Testing

- Perform airtightness tests and performance evaluations to verify cooling efficiency, durability, comfort, and safety.

V. Packaging and Delivery

-

Packaging

- Use eco-friendly, moisture-proof materials to protect the mask during storage and shipping.

-

Final Inspection

- Conduct a pre-delivery quality check and include detailed user instructions for proper use and maintenance.

VI. Quality Control

- Strictly monitor all stages:

- Raw material inspection

- Mold precision

- Heat-pressing parameters (temperature, time)

- Water circulation performance

- Final product compliance with standards