Pipe welding and bag body sealing technology of disposable liquid storage bag system (SUS)

I. Pipeline Welding Technology

Aseptic Thermoplastic Tube Welding

- Medical-grade thermoplastic materials (e.g., PE/PP) are thermally fused to achieve seamless connections between tubes and bags, eliminating leakage risks associated with traditional adhesive or mechanical methods.

- Typical equipment includes automated bag mounting and sealing machines integrated with cleanroom-specific heat sealing devices (e.g., Puxiong series) to ensure weld strength and chemical resistance.

.jpg)

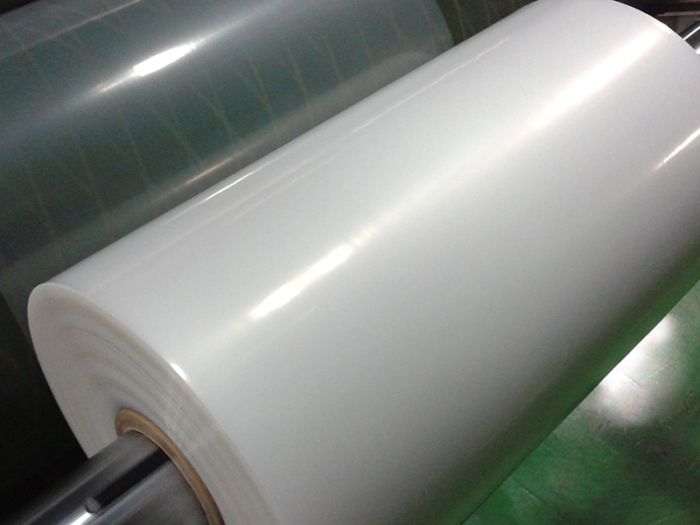

Multilayer Co-extruded Film Welding

- Simultaneous heat sealing of multilayer films enhances weld pressure resistance, suitable for high-viscosity fluid transfer.

- Post-weld integrity is verified via pressure decay method (e.g., Leak-SUS tester) with detection sensitivity up to 1 Pa.

II. Bag Sealing Technology

Triple Sealing Mechanism

- Peripheral Weld Ring: Full-circumference welded ring design.

- Elastic Sealing Gasket: Silicone or EPDM materials auto-compensate for gaps caused by vibration or thermal deformation.

- Spiral Sealing Band: Self-tapping bolts combined with sealing rings form spiral compression to resolve dynamic leakage.

Online Monitoring & Integrity Testing

- Real-time pressure decay monitoring via Leak-SUS bag integrity testers ensures compliance with GMP requirements.

- Test pressure range: 0-5 kPa; modular design adaptable to various bag specifications.

III. Technical Application Case

- Freeze-Thaw Bag Welding: Blown co-extrusion technology prevents weld cracking at -80°C.

IV. Industry Standards & Trends

- Material Selection: Preference for USP Class VI certified films to ensure biocompatibility.

- Automated Production: Heat sealing conducted in ISO Class 5 (Grade B+A) cleanrooms to minimize human-induced contamination.

For detailed equipment parameters or sealing validation methods, please specify technical requirements.