How is the drainage bag thermally formed?

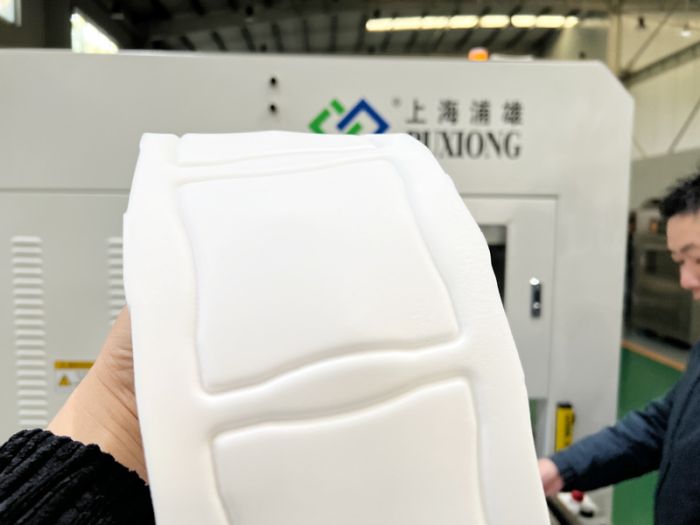

I. Thermoforming Equipment

The drainage bag heat-sealing machine is the primary production equipment. It utilizes high-frequency heat-sealing technology to heat, melt, and press-bond the materials of the drainage bag (such as PVC, EVA, etc.), forming a sealed drainage bag structure. This equipment is widely used in medical product manufacturing, packaging, and related industries.

II. Thermoforming Materials

Drainage bags are typically made from medical-grade polymer materials, such as PVC and EVA. These materials exhibit excellent biocompatibility and mechanical strength, ensuring they meet the requirements for medical applications.

III. Thermoforming Process

- Material Preparation: Medical polymer materials are cut and preprocessed according to the design dimensions and shape of the drainage bag.

- Heating and Melting: The prepared materials are placed in the heating zone of the heat-sealing machine, where high-frequency electromagnetic fields heat the material surfaces to a molten state.

- Press-Bonding and Sealing: While the materials are molten, the machine’s pressure device presses them together to form a sealed drainage bag structure.

- Cooling and Setting: After press-bonding, the drainage bag is placed in a cooling zone to solidify its shape and ensure stable sealing performance.

IV. Safety Protection Devices

Drainage bag heat-sealing machines are typically equipped with safety mechanisms such as overcurrent relays and spark suppressors. These devices automatically cut off power or issue warnings in cases of overload or abnormal operation, safeguarding both the equipment and operators.

V. Quality Control

During thermoforming, strict control of parameters—including raw materials, heating temperature, and pressure—is essential to ensure the drainage bags meet medical standards. Finished products undergo quality inspections and testing to verify sealing integrity, mechanical strength, and other critical performance indicators.