What medical materials are suitable for high frequency hot pressing edge sealing process

High frequency hot pressing edge sealing technology is widely used in the medical field, mainly suitable for the following medical materials:

1.Medical packaging materials containing PVC:

Such as PVC plastic blister, blister, etc., these materials are often used in the packaging of medical devices, such as battery blister hanging card packaging. High-frequency hot pressing edge sealing process can ensure the sealing and safety of these packages.

2.Medical sponge dressing:

As mentioned above, medical sponge dressings need to have good liquid absorption performance, air permeability and plasticity, as well as a strong edge sealing effect. High-frequency hot pressing edge sealing process can meet these requirements and ensure the quality of the dressing is stable and safe and reliable.

3.Plastic parts of medical devices:

Plastic parts such as balloon catheters that require high strength, seamless and sealed connections. High-frequency hot pressing edge sealing process can heat up plastic materials and fuse them together through high-frequency energy, realize the welding of these parts, and improve the durability and safety of the product.

4.Medical mask:

High-frequency hot pressing edge sealing process can also be used to manufacture medical masks, by hot pressing to fuse multiple layers of materials together to form a mask with specific functions. This production method not only improves the protective performance of the mask, but also ensures the hygiene and quality of the product.

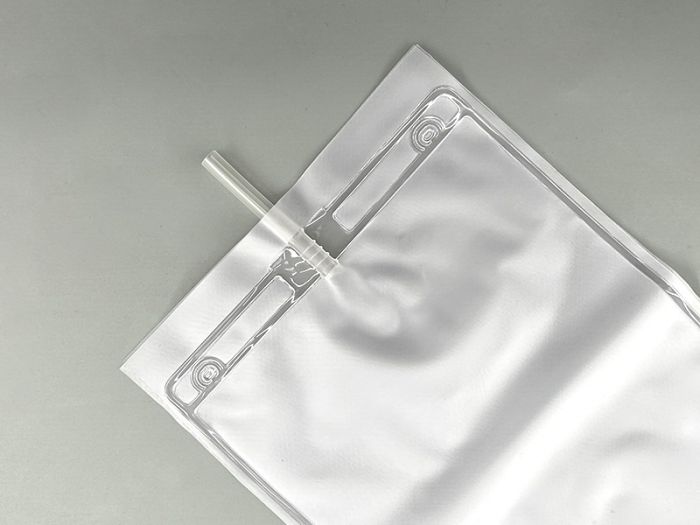

5.Medical fluid bags:

Such as blood bags, infusion bags, urine bags, etc., these fluid bags require a high degree of sealing and sterility. The high-frequency hot pressing edge sealing process can ensure the hygiene and sealing effect of the welding process and meet the strict requirements of medical fluid bags.

The high-frequency hot pressing edge sealing process is suitable for various medical materials that require high strength, seamless and sealed connections, such as packaging materials containing PVC, medical sponge dressings, plastic parts of medical devices, medical masks, and medical fluid bags. This process can not only improve production efficiency, but also ensure the stable quality and safety and reliability of the products, providing strong support for the development of the medical industry.