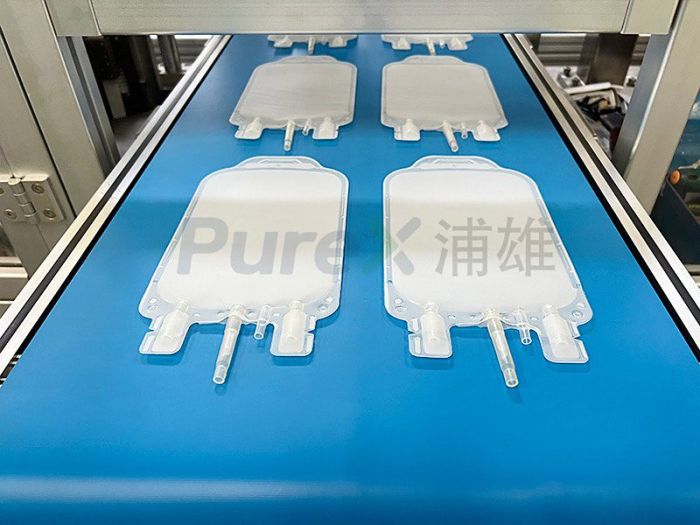

Fully automatic blood bag production line

The high-frequency heat sealer for disposable PVC plasma bags in a fully automated blood bag production line is a key piece of equipment in the medical packaging industry, primarily used for high-frequency welding, heat-sealing, and sealing PVC blood bags. The following are its core features and applications: Core Function

The high-frequency heat sealer uses a high-frequency electromagnetic field to polarize PVC molecules and generate heat to fuse them, sealing and encapsulating the blood bag. Its dual-head design allows it to process two workpieces simultaneously, significantly improving production efficiency.

Operating Principle

High-frequency Electromagnetic Field: Utilizes high-frequency current to generate an electromagnetic field, polarizing PVC molecules and rapidly heating them.

Temperature Control: Equipped with a stepless temperature control mechanism, it precisely adjusts the welding temperature to ensure that the fusion quality meets medical-grade standards.

Pressure and Time Management: A control system adjusts pressure and welding time in real time to ensure seal strength and airtightness.

Key Technical Features

Automated Design: Automates feeding, positioning, welding, and finished product output, reducing manual intervention.

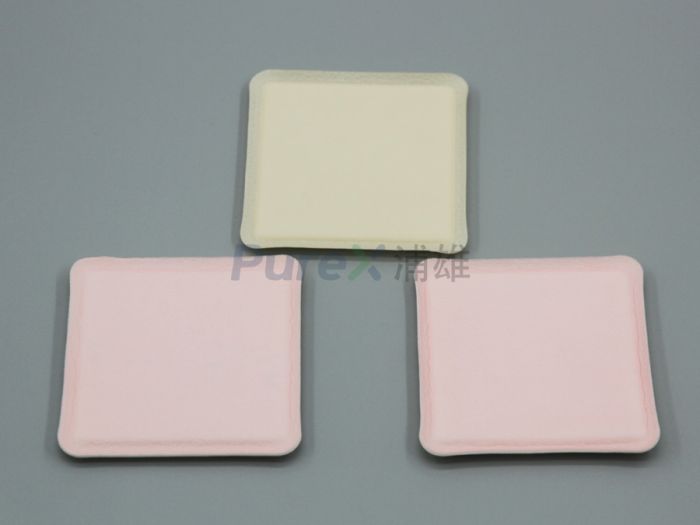

Safety Protection: A built-in electronic thyristor detects overcurrent and automatically maintains a static state in the event of a power or gas outage. Compatibility: Suitable for PVC blood bags of varying specifications and thicknesses, and can be customized to specific sizes and shapes.

Application Scenarios

This equipment is widely used in medical settings such as blood banks and hospitals to ensure the sterility and safety of blood bags during transportation and storage. It can also be used to seal other PVC medical supplies, such as infusion bags and urine bags.