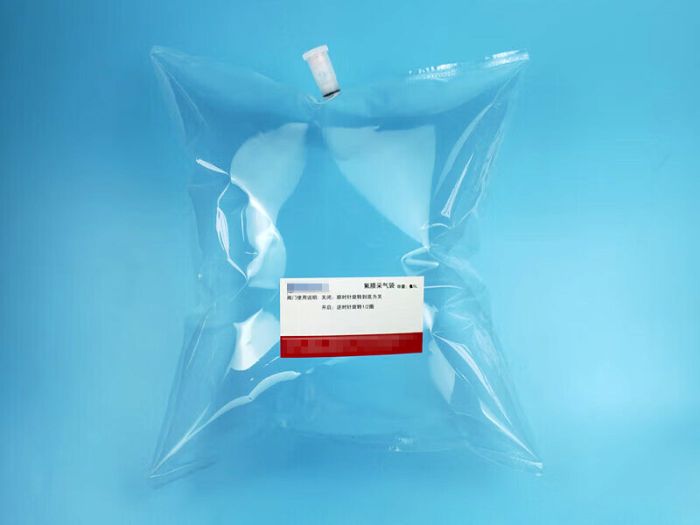

The production process of fluorine material gas collection bags

The manufacturing of fluoropolymer gas sampling bags involves critical steps including material selection, forming, processing, and quality control. The detailed workflow is as follows:

1. Material Selection & Preprocessing

Raw Material Selection:

- Select appropriate fluoropolymers (e.g., PTFE, FEP) based on the bag's intended use.

- Ensure material purity (typically ≥99.9%) to minimize impurity interference.

Preprocessing:

- Clean, dry, and surface-treat fluoropolymer materials (e.g., plasma treatment) to enhance bonding compatibility with sealing components.

2. Forming Processes

The forming methods for fluoropolymer gas sampling bags include:

Hot Press Molding

- Place fluoropolymer films/sheets into molds, then apply heat and pressure to shape the material.

- Advantages: Precise control over bag thickness and geometry; ideal for small batches or customized production.

- Disadvantages: Longer production cycles.

Injection Molding

- Primarily used for producing accessories (e.g., valves, connectors) rather than the bag body.

3. Processing & Assembly

Cutting & Edge Sealing

- Cut formed fluoropolymer materials to required dimensions using high-frequency welding.

- Seal edges via heat fusion or adhesive bonding to ensure airtightness.

Valve & Port Installation

- Install valves (e.g., check valves, shut-off valves) and ports (e.g., threaded ports, quick-connect fittings) for gas sampling and discharge.

- Critical Note: Valve materials must be chemically compatible with fluoropolymers to prevent corrosion or leakage.

Surface Treatment

- Apply anti-static coatings or specialized surface treatments to minimize gas adsorption or electrostatic accumulation.

4. Testing & Quality Assurance

Leakage Testing

- Verify airtightness using helium leak detectors or pressure decay methods to ensure leak-free performance.

Chemical Resistance Testing

- Expose bags to target gases to validate corrosion resistance and chemical stability.

Mechanical Performance Testing

- Evaluate tensile strength, tear resistance, and pressure tolerance to confirm compliance with operational requirements.

Cleanliness Inspection

- Analyze inner wall contaminants using particle counters or spectroscopic analyzers to prevent gas sample contamination.