The material of the leg bag and high-frequency heat sealing technology

The Synergistic Relationship Between High-Frequency Welding and Leg Bag Material Selection in Technical Compatibility and Functional Realization

The interaction between high-frequency welding and material selection for leg bags is a collaborative relationship between technical compatibility and functional realization. Both factors, through the alignment of material properties and process principles, jointly determine the leg bag's sealing performance, safety, and production efficiency. A detailed analysis follows:

I. Material Selection Must Meet High-Frequency Welding Process Requirements

High-frequency welding utilizes a high-frequency electromagnetic field (27.12 MHz or 40.68 MHz) to generate heat via molecular polarization and friction within plastics, achieving fusion. Therefore, leg bag materials must exhibit the following characteristics:

-

Molecular Polarization Capability

- PVC (Polyvinyl Chloride): Contains chlorine atoms, resulting in high polarization rates. It is the traditional mainstream material for high-frequency welding. While PVC offers high transparency and flexibility, standard PVC may release plasticizers. Medical-grade PVC (e.g., with citrate-based plasticizers) is required to meet healthcare safety standards.

- TPU (Thermoplastic Polyurethane): Excellent biocompatibility, with tensile strength three times that of PVC. Its molecular structure includes polar groups (e.g., ester/ether groups), enabling uniform welding via high-frequency fields. For example, a TPU leg bag can withstand 200 N pressure without rupture, making it suitable for post-surgical rehabilitation scenarios requiring load-bearing capacity.

- EVA (Ethylene-Vinyl Acetate Copolymer): Lightweight (density: 0.91–0.94 g/cm³) but low polarization capability. It is typically combined with PVC or TPU to enhance welding performance.

-

Thermal Stability and Melting Point Control

- High-frequency welding requires precise temperature control (e.g., PVC melts at 160°C but is heated below 150°C to avoid carbonization or deformation). TPU’s wide melting range (140–220°C) allows better adaptability to localized heating in high-frequency processes.

-

Uniform Thickness

- Material thickness deviation must be ≤0.1 mm. Non-uniform thickness disrupts electromagnetic field distribution, reducing weld strength. Medical leg bags typically use TPU or PVC with 0.3–0.5 mm thickness, achieving a sealing performance of -80 kPa (no leakage for 10 minutes).

II. High-Frequency Welding Drives Material Innovation

-

Composite Material Applications

- TPU + Nylon Composites: To balance flexibility and strength, TPU-nylon composites are used. Optimized mold designs (e.g., gradient heating molds) enable cross-layer fusion during welding, achieving peel strength of 15 N/cm—far exceeding traditional adhesive bonding (3–5 N/cm).

- PTFE (Polytetrafluoroethylene) Filter Membrane + PVC: PTFE membranes (0.2 μm pore size) filter 99.97% of bacteria. High-frequency welding ensures seamless sealing, preventing gas reflux and cross-contamination.

-

Functional Coating Integration

- Silver-Ion Antibacterial Coating: High-frequency welding binds silver ions to PVC surfaces, achieving 99.6% antibacterial rates and extending leg bag usage to 3 days (vs. daily replacement for conventional products).

- Waterproof Breathable Membranes: PTFE-EVA composites, welded via high-frequency processes, achieve a breathability rate of 800 g/m²·24h, maintaining dryness and reducing pressure ulcer risks.

III. Synergistic Optimization Cases for Materials and Processes

-

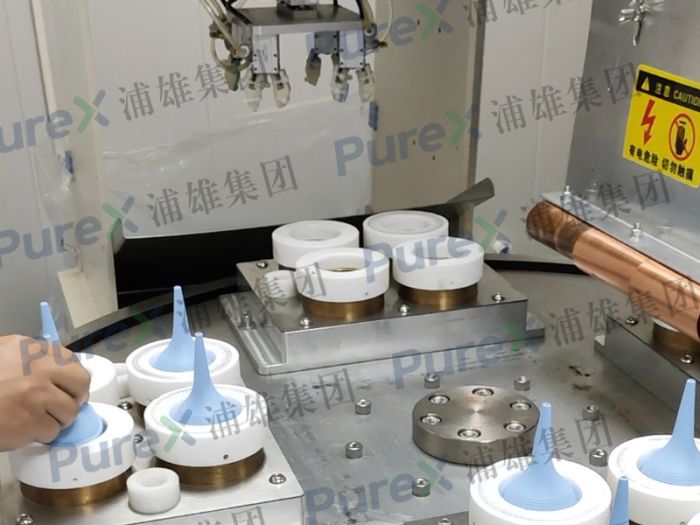

Medical Blood Bag Production

- Fully automated blood bag production lines integrate high-frequency welders for material feeding, flattening, printing, tubing insertion, welding, and inspection. PVC welding uniformity improves by 30%, with annual loss reduced by 40% (via spark protection systems minimizing mold damage).

-

Lightweight Sports Leg Bag Design

- EVA casing (density: 0.92 g/cm³) + carbon fiber framework, combined with high-frequency welding, reduces weight by 30% while enhancing impact resistance by 50%. Mold cooling systems improve temperature uniformity by 25%, minimizing thermal stress cracks.

-

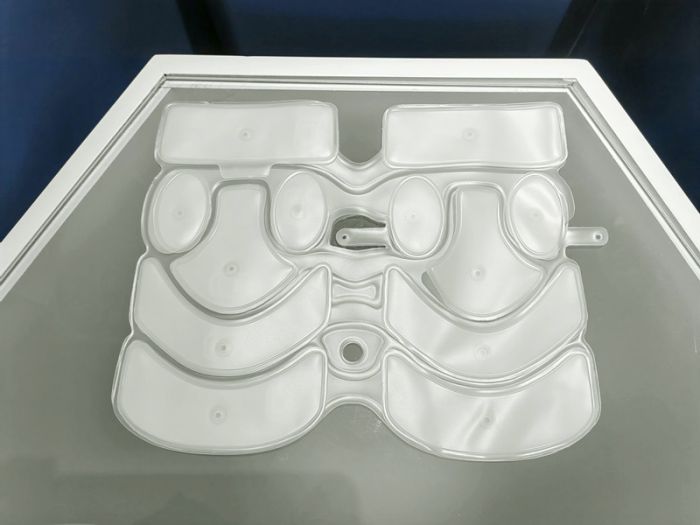

Air-Tightness for Rehabilitation Leg Bags

- TPU air chambers in pneumatic massage leg sleeves use high-frequency welding to interconnect cascaded air cavities. Corrugated structural designs increase inflation height by 30%, while welding ensures airtightness at -80 kPa (no leakage for 10 minutes).