Disposable multi-layer co-extruded bag heat sealing machine

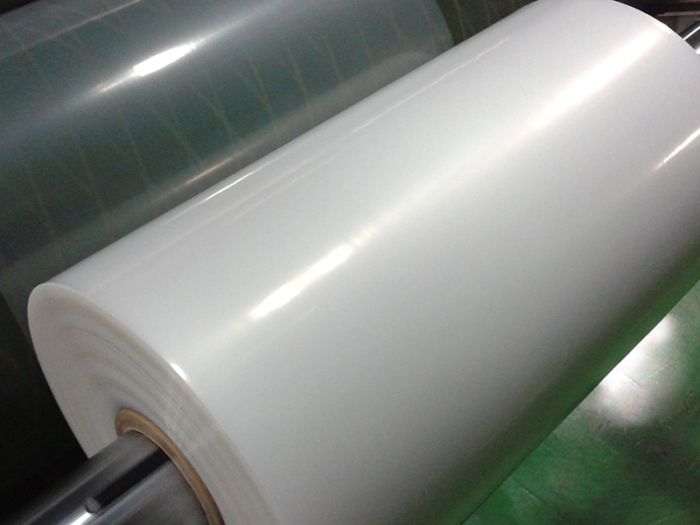

The single-use multi-layer coextrusion bag heat sealing machine is a high-precision device designed for applications in bioprocessing, food packaging, and medical industries. Its core function is to thermally fuse specific layers of multi-layer coextruded film materials (e.g., LDPE, LLDPE, EVA, TPU) using heat-sealing technology, forming airtight, water-resistant, and puncture-resistant seals.

Technical Specifications: Key Requirements for Multi-Layer Coextrusion Film Heat Sealing

-

Material Compatibility

- The heat-sealing layer of multi-layer coextruded films typically employs blends of low-density polyethylene (LDPE) and linear low-density polyethylene (LLDPE), or flexible materials such as ethylene-vinyl acetate (EVA) and thermoplastic polyurethane (TPU). These materials must meet:

- Seal Strength: Welding strength ≥40N/15mm to ensure leak-proof integrity.

- Biocompatibility: Suitable for cell culture bags, requiring sterilization compliance and absence of low-molecular-weight leachables.

- The heat-sealing layer of multi-layer coextruded films typically employs blends of low-density polyethylene (LDPE) and linear low-density polyethylene (LLDPE), or flexible materials such as ethylene-vinyl acetate (EVA) and thermoplastic polyurethane (TPU). These materials must meet:

-

Heat-Sealing Process Parameters

- Temperature: Precise control to avoid material scorching or weak seals.

- Pressure: Uniform application to ensure full fusion of heat-seal layers.

- Duration: Matched to material thickness for robust and aesthetically consistent seals.

Applications: Cross-Industry Demands from Bioprocessing to Food Packaging

-

Bioprocessing Applications

- Single-use bioreactor bags: Must withstand bending and pressure during manufacturing, transportation, and use, requiring highly reliable seal structures.

- Liquid storage bags, mixing bags, feeding bags: Seal integrity must be verified via heat-seal testers to eliminate leakage risks.

-

Food Packaging Applications

- High Barrier Performance: Multi-layer coextruded films block oxygen (permeability <0.1 mL/m²·day·atm) and water vapor (transmission rate <0.5 mL/m²·day·atm), extending shelf life.

- Extreme Temperature Resistance: Heat-sealed structures must remain stable under high-temperature retort or cryogenic conditions.

.jpg)