The application of automatic high-frequency welding in medical supplies

Automatic high-frequency welding is also applicable to the following medical products in the healthcare industry:

-

Surgical Warming Blankets

Capable of producing upper body blankets, lower body blankets, shoulder blankets, full-body blankets, under-body blankets, infant blankets, pediatric blankets, lithotomy positioning pads, etc. High-frequency welding ensures the connection and sealing of components, maintaining the integrity and functionality of warming blankets. -

Ostomy Bags

An integrated hot-sealing and cutting machine for ostomy bags enables precise sealing and trimming, ensuring airtightness and user-friendly design. -

Medical Catheters

High-frequency plastic welding machines for medical catheters can weld sleeves of various materials (e.g., PP, PVC, TPU) with differing hardness levels. This achieves robust connections between catheters and accessories while ensuring sealed and smooth weld surfaces. -

Medical Bags

Dual high-frequency rotary medical bag welding machines are used for one-step forming of infusion bags, blood bags, drainage bags, irrigation bags, and nutritional bags. They enable continuous welding of bags and tubes, enhancing production efficiency and product quality. -

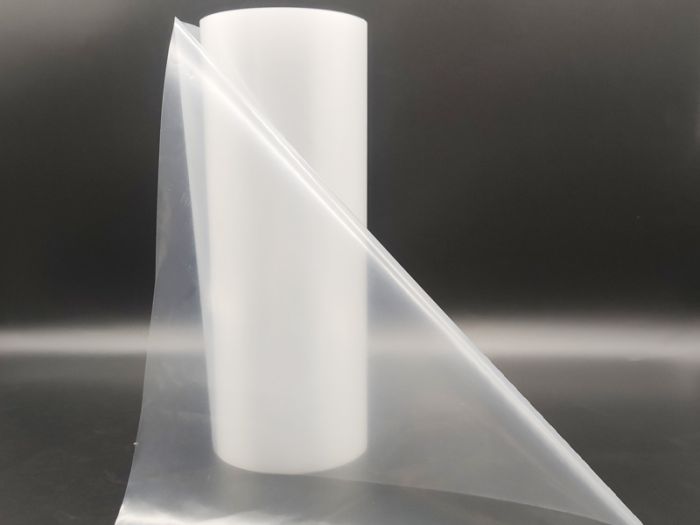

Paper-Plastic Packaging

Paper-plastic sealing machines are suitable for welding plastic blister trays (PET, PETG, APET) to medical-grade dialysis paper or Tyvek® materials, ensuring airtight packaging and effective sterilization. -

Anti-Decubitus Air Cushions

High-frequency welding/cutting machines for anti-decubitus products allow simultaneous welding and trimming of inflable medical items (e.g., air mattresses, seat cushions), improving production efficiency.

.jpg)