Disposable medical blood transfusion devices: Application of heat-sealing connection technology

Medical disposable blood transfusion set

Medical disposable blood transfusion set is a medical device composed of a variety of accessories, mainly used to save patients with massive bleeding or perform blood transfusion during surgery. Its main raw materials are medical grade polyvinyl chloride (PVC), ultra-low density polyethylene (PE) or other medical grade polymer materials, which must meet the specific requirements of medical devices, such as biocompatibility, chemical resistance, aging resistance, etc. The blood transfusion set is usually composed of accessories such as a protective cover, a puncture device, a blood and blood product filter, a dropper, a dropper, a dropper outlet hose, a flow regulator, an insert-type conical joint, and a liquid stop injection piece. These components work together to ensure the safety and effectiveness of the blood transfusion process.

Heat-sealing process

The heat-sealing process is a key link in the production process of disposable medical transfusion sets. It involves the firm connection of components such as the drip bucket and the hose to ensure the sealing, sterility and safety of the transfusion set. The following is a general description of the heat-sealing process:

Material pretreatment:

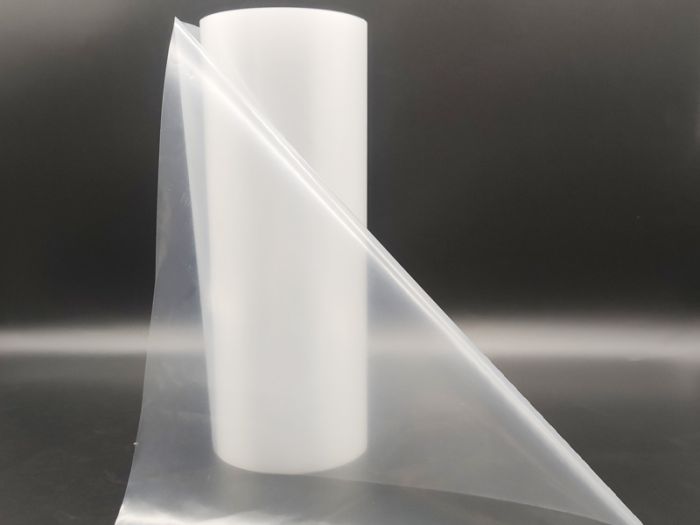

The drip bucket and the hose are usually made of medical-grade polymer materials, such as PVC, PE or polyolefin (PO).

Before heat-sealing, the connection ends of the drip bucket and the hose need to be pretreated, including cutting, cleaning, drying and other steps to ensure the flatness and cleanliness of the connection surface.

Heating and pressing:

The heat-sealing connection melts the material at the connection part by heating, and then quickly presses the drip bucket and the hose together.

Parameters such as heating temperature, heating time, and pressure need to be precisely controlled to ensure the strength and sealing of the connection. These parameters are usually determined by medical device manufacturers according to their own technical specifications and quality control requirements.

Modern heat-sealing machines usually use electric heating wire heating or high-frequency electromagnetic field induction heating to achieve efficient and accurate material connection.

Post-processing:

After the connection is completed, post-processing is required, such as cooling, inspection, packaging and other steps.

The cooling process helps the material solidify and form a strong connection.

The inspection step ensures that the various properties of the blood transfusion set meet the relevant standards and requirements.

Related national standards and quality control

The production of disposable medical blood transfusion sets must comply with relevant national standards, which are usually formulated by medical device regulatory agencies in various countries. The following are some common standards:

ISO 11193: A series of standards for the biological evaluation of medical devices to ensure that blood transfusion sets are harmless to the human body during use.

ISO 13485: The quality management system of medical devices is used for regulatory requirements to guide medical device manufacturers to establish and maintain a quality management system.

YY/T 0287: Special requirements for the application of ISO 13485 in the medical device industry, which are supplemented and refined for the special circumstances of the Chinese medical device industry.

GB 8369: A series of national standards for disposable blood transfusion sets (China), which specifies in detail the technical requirements, test methods, inspection rules, etc. of blood transfusion sets.

Medical disposable blood transfusion sets and their heat-sealing connection process are key links to ensure the safety and effectiveness of the blood transfusion process. Through strict material selection, precise process control and comprehensive quality testing, blood transfusion set products that meet national standards and patient needs can be produced. With the continuous development of science and technology, the application of advanced equipment such as heat-sealing machines will further improve the production efficiency and product quality of blood transfusion sets.