Sterile isolation bag

I. Definition and Applications

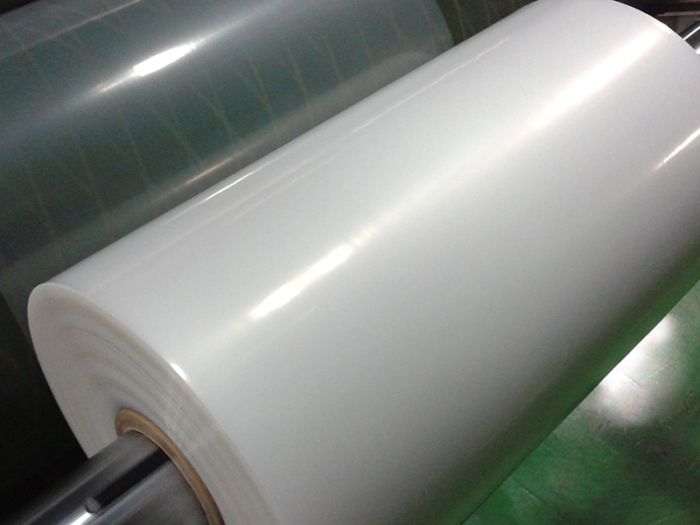

Sterile isolation bags are manufactured from polyethylene granules through processes including film blowing, cutting, heat sealing, vacuum packaging, and sterilization in a controlled cleanroom environment. Known for their sterility, non-toxicity, excellent low-temperature resistance, chemical stability, and electrical insulation properties, these bags are widely used for the transportation and temporary storage of sterile active pharmaceutical ingredients (APIs), sterile pharmaceutical excipients, and sterile finished products. They also serve as intermediate packaging for sterile stoppers during transit from cleaning to filling lines. In the food industry, sterile bags can be combined with cardboard and aluminum foil to form composite packaging containers, primarily providing a barrier against liquid leakage and microbial contamination.

II. Production Environment and Manufacturing Process

According to industry standards, sterile bags must be produced in facilities with a Grade C or higher cleanroom classification. Cleanroom classification is determined based on airborne particle counts and settling microbial levels. The production process involves film blowing, cutting, heat sealing, vacuum packaging, and sterilization. Each step requires stringent quality control to ensure the final product’s sterility.

III. Key Features

- Sterility: Rigorous production and sterilization processes ensure an aseptic interior, protecting packaged items from microbial contamination.

- Chemical Stability: The bags exhibit high chemical inertness, minimizing interactions with contents to preserve safety and efficacy.

- Low-Temperature Resistance: Maintains physical integrity and sterility under refrigeration or freezing conditions, ideal for temperature-sensitive products.

- Barrier Properties: Effectively blocks liquid leakage and microbial ingress, safeguarding contents from external environmental factors.

IV. Pricing and Market Trends

Prices of sterile isolation bags vary depending on brand, specifications, material composition, and other factors. A wide range of products is available in the market, allowing consumers to select options based on needs and budgets. Driven by rapid growth in healthcare, food, and related industries, demand for sterile isolation bags continues to rise, indicating robust market prospects.

V. Usage and Storage Guidelines

- Ensure bags remain sterile during use; avoid contamination when opening or handling.

- Store in a dry, cool, and well-ventilated area, away from direct sunlight, high temperatures, or humidity.

- Regularly inspect expiration dates and physical integrity; replace expired or damaged bags promptly.

As a high-tech packaging material, sterile isolation bags play a vital role in medical, pharmaceutical, and food industries. Strict adherence to operational and storage protocols is essential to maintain their sterility and safety throughout the product lifecycle.