Connection and sealing technology for catheters, blood tubes, and endotracheal tubes

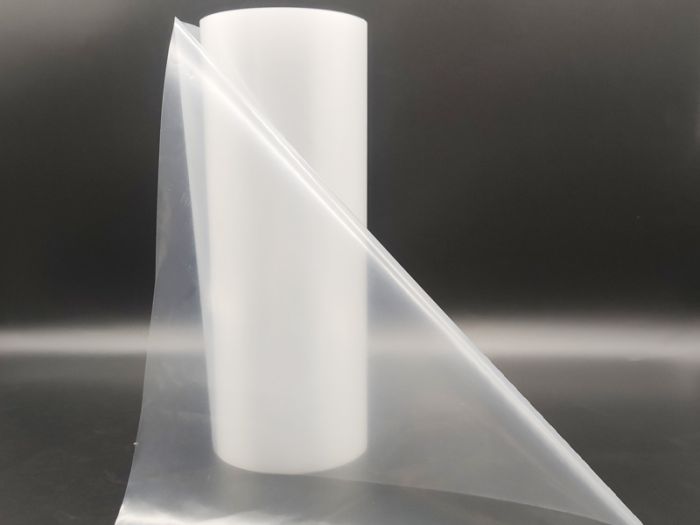

High frequency heat sealing machines are widely used in the medical industry, especially in the production of catheters and hoses. Catheters, blood transfusion tubes, endotracheal tubes and other equipment are usually made of flexible plastic materials (such as polyvinyl chloride (PVC), silicone, etc.), which need to be connected and sealed by high frequency heat sealing technology to ensure their functionality and safety.

1. Connection and sealing of catheters

Material: Catheters are usually made of materials such as soft PVC, silicone or thermoplastic elastomer (TPU), which have good elasticity and heat-sealability.

Application: During the production of catheters, multiple parts (such as tube mouths, joints, tube sleeves, etc.) may need to be connected. The high-frequency electromagnetic waves generated by the electrodes of the high-frequency heat sealer heat the connection parts of the catheter, quickly soften the plastic surface, and heat-seal it together to form a firm and sealed connection.

Sterility: Since catheters are usually used in the body, maintaining sterility is crucial. High-frequency heat sealing technology minimizes the chance of external contamination by rapid heating and sealing. The connection and sealing process is usually carried out in a clean room to ensure the hygiene of the operating environment.

2. Sealing of blood and infusion tubes

Material: Blood and infusion tubes are usually made of materials such as polyvinyl chloride (PVC) or low-density polyethylene (LDPE), which have high flexibility and durability.

Application: In the production process of blood and fluid tubes, it is often necessary to connect the ports of the hoses with other parts (such as connectors, valves, etc.) or seal them. The high-frequency heat sealer heats the surface of the hose and connector materials to soften them and perform tight heat sealing to ensure that the joints are firm and leak-free.

Sterility: High-frequency heat sealing technology can seal quickly, reduce the time exposed to the air, and ensure the sealing of the pipeline, thereby ensuring the safety and hygiene of blood and fluid tubes during use.

3. Connection of tracheal tubes

Materials: Tracheal tubes are usually made of soft and elastic materials such as silicone, PVC or TPU.

Application: In the production process of tracheal tubes, it may be necessary to connect the two ends of the tube with adapters, connecting tubes or tracheal interfaces. The high-frequency heat sealer uses the heat generated by high-frequency current to quickly heat the surface of the tube and accessories, melt them and form a firm heat-sealed connection. This ensures that the tracheal tube can remain unobstructed and leak-free during medical operations.

Sterility: High-frequency heat sealers can complete the production and sealing of tracheal tubes in a strict sterile environment, ensuring that the tubes are not contaminated by bacteria during use.

4. Heat sealing and connection of other hoses

High-frequency heat sealers are also commonly used for the connection and sealing of other medical hoses, such as anesthesia tubes, urinary catheters, gastrointestinal catheters, etc. These hoses usually need to be connected with various accessories, such as valves, joints and adapters. High-frequency heat sealers can ensure that the parts are firmly connected and tightly sealed.

Advantages of high-frequency heat sealers in connecting catheters and hoses:

Precise control: High-frequency heat sealers can accurately control the temperature, pressure and time of heat sealing to ensure that the connection between the catheter and the hose is firm and leak-free.

Pollution-free operation: The heat sealing process does not require an external heat source and can be completed in a short time, reducing possible contamination and contact time during the production process and maintaining a sterile environment.

High efficiency: High-frequency heat sealers can quickly and accurately handle large quantities of hose connections, improve production efficiency, and meet the medical industry's needs for large-scale production.

Adapt to a variety of materials: High-frequency heat sealing machines can handle a variety of different plastic materials, such as PVC, silicone, TPU, etc., and have a wide range of applicability.

Summary:

High-frequency heat sealing machines provide an efficient and precise solution for connecting and sealing materials in the production of medical hoses such as catheters, blood transfusion tubes, and endotracheal tubes. Through this technology, not only can the quality and safety of the products be guaranteed, but also these medical devices can be ensured to have good performance and sterility when in use.