What are the materials and heat-sealed production methods of disposable blood transfusion sets?

Disposable blood transfusion sets are important medical devices. The selection of materials and heat-sealing production methods is crucial to ensure the safety and effectiveness of the blood transfusion process. The following is a detailed analysis of the materials and heat-sealing production methods of disposable blood transfusion sets:

Ⅰ. Materials of disposable blood transfusion sets

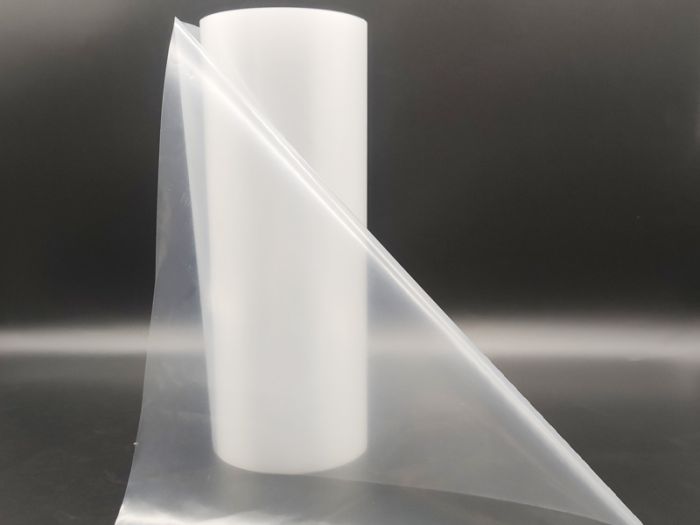

The main materials for disposable blood transfusion sets include medical grade polyvinyl chloride (PVC) and TPU (thermoplastic polyurethane).

1.Medical grade polyvinyl chloride (PVC):

PVC is the traditional material for making disposable blood transfusion sets. It is widely used because of its good biocompatibility, non-toxicity, tastelessness, corrosion resistance and other characteristics.

Disposable blood transfusion sets made of PVC usually have high strength and toughness, which can meet various needs during blood transfusion.

2.TPU (thermoplastic polyurethane):

TPU is a new type of material that has attracted much attention due to its excellent flexibility and elasticity.

Disposable blood transfusion sets made of TPU perform well in the bending and recovery process, which can reduce the discomfort of patients.

In addition, TPU also has good biocompatibility and wear resistance, which can ensure the safety and effectiveness of the blood transfusion process.

Ⅱ. Heat sealing production method of disposable blood transfusion sets

Heat sealing is an important link in the production process of disposable blood transfusion sets, which involves the key technologies of sealing, sterility and safety of blood transfusion sets.

1.Heat sealing principle:

Heat sealing is a production process that uses high-frequency current or heat energy to melt the blood transfusion tube material instantly on the contact surface through the heat sealing mold, and tightly combine them under the action of pressure.

2.Heat sealing equipment:

The heat sealing production of disposable blood transfusion devices requires the use of special heat sealing equipment, such as high-frequency heat sealing machines, heat presses, etc.

These equipment can achieve accurate heat sealing of blood transfusion tubes to ensure the sealing and integrity of blood transfusion devices.

3.Heat sealing process:

Preparation: Cut the blood transfusion tube material into appropriate lengths as required, and clean and pre-treat it.

Place the mold: Place the processed tube material in the heat sealing mold to ensure that the contact surface is flat and aligned.

Start the heat sealing equipment: According to the selected material and equipment requirements, set the appropriate heat sealing temperature, pressure, time and other parameters, and start the heat sealing equipment.

Apply pressure: During the heat sealing process, apply appropriate pressure to the mold to make the tube material tightly combined while melting.

Cooling and shaping: After the heat sealing is completed, let the blood transfusion set tube cool in the mold for a period of time to ensure the stability of its shape and size.

Quality inspection: The heat-sealed blood transfusion set is subjected to quality inspection, including sealing test, sterility test, etc., to ensure that it meets the relevant standards and requirements.

4.Heat-sealing quality control:

During the heat-sealing production process, it is necessary to strictly control parameters such as heat-sealing temperature, pressure and time to ensure the sealing and integrity of the blood transfusion set tube.

At the same time, it is also necessary to conduct quality inspection and testing on the heat-sealed blood transfusion set to ensure that it meets the relevant medical standards and requirements.

The material and heat-sealing production method of the disposable blood transfusion set are crucial to ensure the safety and effectiveness of the blood transfusion process. When selecting the material and heat-sealing production method, it is necessary to comprehensively consider the actual situation of the patient and the blood transfusion needs to ensure that the best blood transfusion solution is provided to the patient.